Collated Screws

Production Process

Screws Heading

The material of wire is from CNINA STEEL company in Taiwan, the quality of wire and dimension are being controlled carefully.

Screws Heading

Heat Treatment

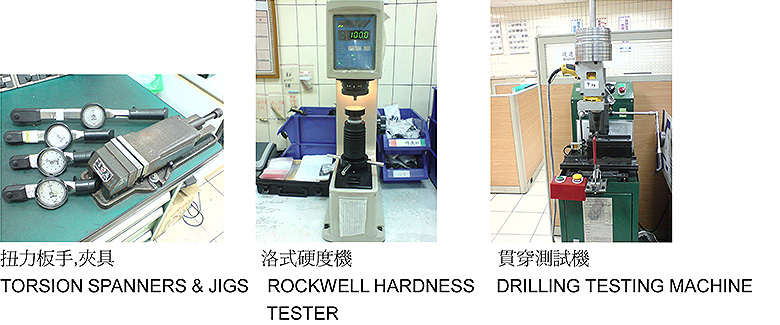

Drilling Test and Torsion Test.

Plating & Coating

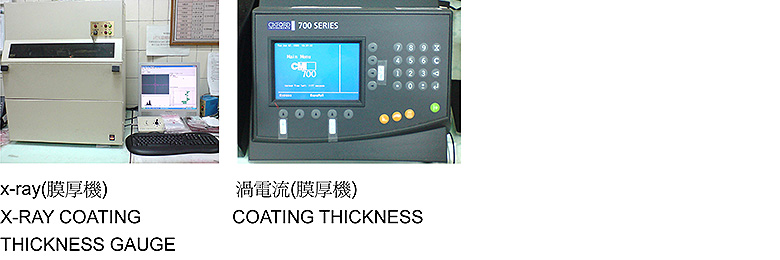

Coating Thickness and Salt Spray Test.

Plastic Strip Making Process

The press machine will inspect plastic strips automatically, when they are not measure up, the machine stops, and notices the operator, Good qualities of plastic strips make collated screws easy and smooth in use.

Screws Collating Process

Machine will inspect for defective screws automatically during collation. (Output: 2000 pcs/min)

P.S. Keep the main structure secret

Sampling Inspection

We sample the finished products for testing in different brand screw gun.

Breaking plastic strips test.

Packing Process

1. Inner boxes packing & final inspection: Packing staffs inspect finished products. We make sure that every collated screw goes through a complete process of quality control and quality assurance before delivery.

2. Pallet packing: Avoid damaging the goods when they deliver.

Contact Detail

| CEO: | Mr. Joey Yang |

| Contact: | Sales Manager : Angela Chen |

| Address: | No.29, Lane 32, Shi Liou St, Tali Dist., Taichung City, Taiwan |

| TEL: | 886-4-24964485 / 24968558 |

| FAX: | 886-4-24968559 |

| Email: | zenyoung@ms72.hinet.net |

| URL: | http://www.allproducts.com/machine/zenyoung/

http://www.zen-young.com.tw |

| ZIP: | 412 |